Woodturning Terms

An explanation of terms, tools and equipment used in woodturning.

General Definitions

Woodturning: The craft of using a lathe to produce objects from wood between centers or held to the headstock via chuck or faceplate.

Green Wood: Freshly cut logs or timber. Usually used to rough out forms to allow them to dry and then return later. Many times used to a final form and allowed to warp artistically. The term refers to wet logs.

Definitions of Forms Produced on the Lathe

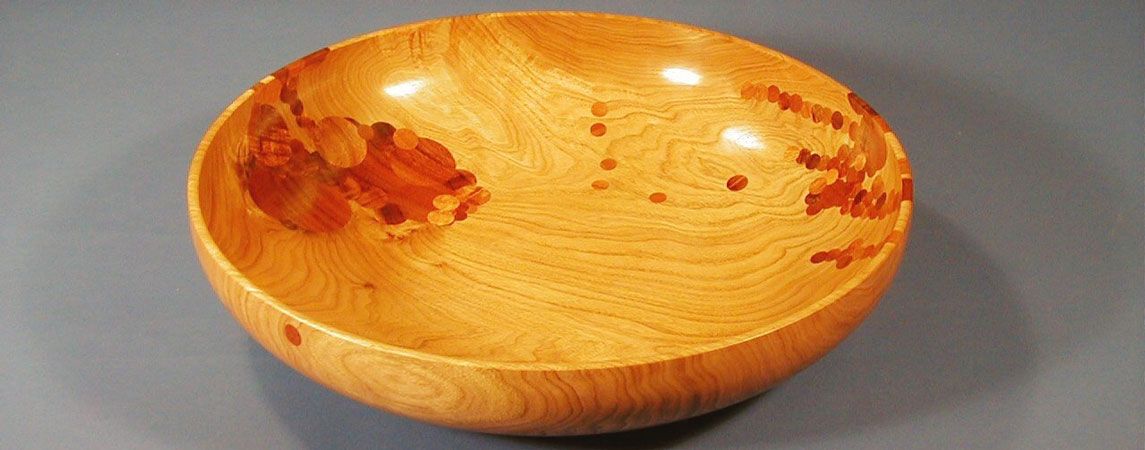

Open Form: A vessel in which the lip of the form is continuously increasing in diameter.

Bowl: An open form.

Closed Form: A vessel in which the lip of the form increases from the bottom then decreases at some point toward the top.

Hollow Form: A closed form with a small opening at the top.

Spindle: A linear turned piece with the grain running from end to end.

Definitions & Descriptions of Equipment & Tools

Lathe: A device that holds and turns wood while a tool is used to shape the wood.

Headstock: The assembly on the lathe that contains the driving mechanism for the lathe. It is attached to the lathe bed and usually has a spindle for mounting faceplates and inserting spurs or centers.

Tailstock: It is an assembly that moves along the bed of the lathe and can be clamped at any desired position on the bed. It contains a spindle that will hold dead centers or live centers and is generally but not exclusively used in spindle turning.

Faceplate: A metal or wood disk that mounts on the headstock spindle and woodstock is mounted to it with screws through the holes in the faceplate.

Chuck: Any device that holds wood in either jaws or wood is fitted into a cylinder of the chuck. The chuck is mounted on the headstock spindle for working the wood.

Gouge: A toolthat has a flute and produces a cutting rather than scraping action.

Roughing Gouge: A gouge with fairly thick walls that is used to rough out and round stock to cylindrical shape very fast. The edges are not ground back and the angle around the whole edge is about 40 degrees. By rolling the gouge you can use the whole edge.

Bowl Gouge: A gouge that has a medium to deep flute and is used to rough out and finish the insides of bowls. The deeper flute is easier to control and will remove wood faster than other gouges.

Side-Ground: Gouge A gouge that has one or both of the sides ground back and can be used in a variety of positions to rough, smooth, shear scrape, etc.

Spindle Gouge: A gouge that has a very shallow flute and is used to produce beads and coves primarily in spindle work. (i.e. between centers)

Skew Chisel: Given the name because the cutting edge is at an angle to the side of the tool. The cutting edge is usually ground to an angle of 70 degrees.The length of the bevel is approximately twice the thickness of the steel. Skews are use to make V cuts, beads, tapers and to smooth corners and cylindrical stock. This tool when properly used will give a finished or semi finished surface to the piece it is shaping.

Parting Tool: Are used to make narrow recesses or grooves to a desired depth or to part a piece from the lathe. A common type would be the diamond shape with the center being thicker than the outside edges to give the tool clearance and prevent friction.

Beading Tool: Usually made out of 3/8th inch square stock and having angles between 30 degrees and 45 degrees which is used to make beads and also can be used as a parting tool.

Scraper: Any tool that scrapes the wood off rather than cutting or shearing the wood. A scraper will usually have a very blunt angle and a burr on the edge that does the actual scraping of the wood. Can be compared somewhat to a cabinet scraper

Definitions of Methods & Techniques in Woodturning

Chucking: Mounting or holding a workpiece on some piece of equipment other than a faceplate.

Shear Scraping: A method of using a side-ground gouge or large scraper to smooth a form. Usually a green form.

Parting: Using a parting tool to remove a section of wood down to a certain diameter. A rough cut.

Reverse Chucking: The method of reversing a form on the lathe to turn away the waste at the bottom and finish off the piece.